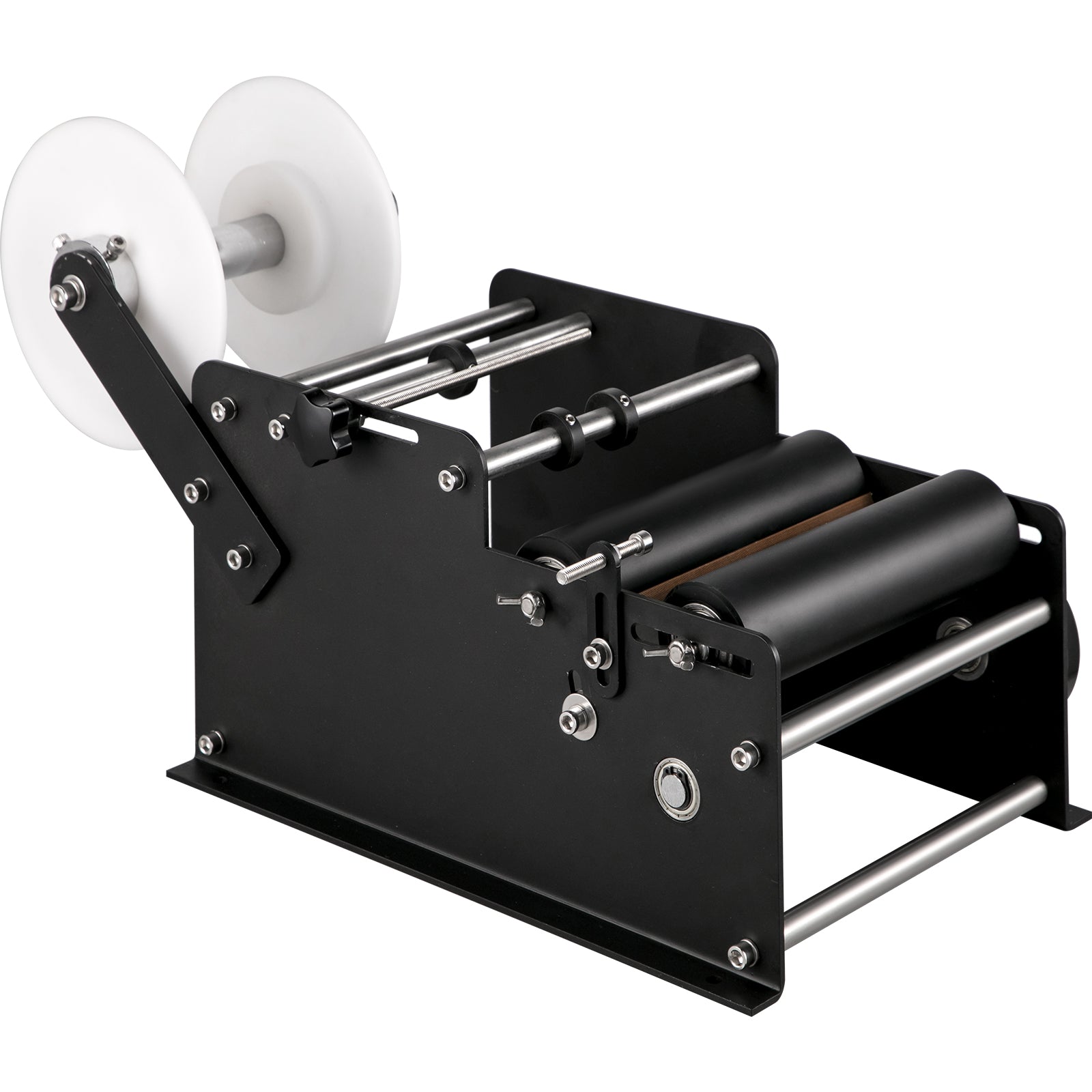

An open-loop displacement control is used on the reel to maintain the tension of the label tape. The driving wheel intermittently drags the label tape to move, the label tape is pulled out from the reel, and the labeling wheel will press the label tape on the box after passing through the labeling wheel. The mechanical system of the labeling machine includes a driving wheel, a rotary automatic labeling machine, a labeling wheel, and a reel.Ģ. The mechanical fixing device separates the boxes by a fixed distance and pushes the boxes along the conveyor belt. At the beginning, the box is fed to the labeling machine at a constant speed on the conveyor belt. Here is an introduction to the working principle of the automatic labeling machine:ġ. Are you curious about the working principle of the labeling machine? Most of the labeled products that we see in our lives are quickly labeled by automatic labeling machines. Label high temperature resistance testing.Label application confirmation with automatic expulsion.Product flow monitoring devices (minimum infeed/outfeed).High-precision adjustment systems for head inclination and revolution counters for adjustment handles.In order to increase their running time and performance, ALline systems can be equipped with optional components, including: Regulating the different units for format/product changes is simple, high-precision and intuitive the labeller is equipped with a function to save the parameters for a specific label-product combination, so they can be easily recalled using a code. Very high-speed labelling, including non-stop version.Partial or complete wraparound labelling.Applying tamper-proof seals to product caps.Labelling of one or more sides with multiple labels.The upper trestle is present even when the cabinet is not installed, thus stiffening the top stabilising belt for increased rigidity of the whole system.ĪLline E can also be equipped with some of the wrap-around units available for ALline C, thus also permitting the labelling of cylindrical products Possible labelling solutionsĪLLINE E labelling machines can be configured in order to satisfy specific labelling requirements, for instance: Precise LabellingĪ sophisticated centralised system synchronises all the labeller components, allowing the speed to be regulated with a single potentiometer, and maintaining precise labelling even during start-up, stopping or slow down stages, synchronised with the entire line. Various different devices are available for product spacing, depending on the required product type and performance.Īlignment and orientation of the products and their stabilisation during the labelling phase is entrusted to various specific tried and tested devices. These conveyors can be of various different sizes. This system can use various types of conveyors for product transport: Their solid and compact base can accommodate two (or more) opposing side ALritma label applicator in an easy-to-access protective cabinet. The performance of ALline E systems can reach 500 pcs/min (depending on the product and label dimensions), or even higher in dedicated configurations.

0 kommentar(er)

0 kommentar(er)